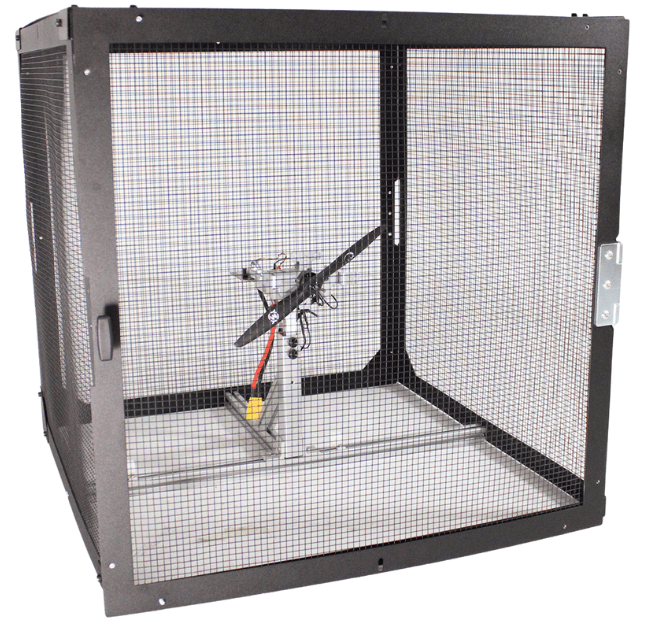

If you are familiar with our products, then you know that our test stands combine thrust and torque measurements with voltage and current to derive the system’s power and efficiency.

Perhaps the most obvious concept for such a tool, and the cheapest to build, is a system involving bearings or bushings. (We would know, since this is what we used in our original Series 1580 design).

What we’ve learned, however, is that using bearings and bushings has a number of disadvantages:

- Bearings and bushings cause friction. The random friction error causes significant uncertainty in the measurement (anywhere from 2 to 20% of the measured force). Even if the design looks rigid, there are micro deformations and movements in the system.

- This leads to hysteresis in the force measurement: the force measured is dependent on the previous force applied. Because of the random nature of friction, it is not possible to correct for the error.

- Another problem with bearings or bushings is that they are very sensitive to misalignment. A small shock, dust or dirt can cause a false reading. The error is not constant due to the random elements that affect it (friction, dust, etc.), so it can not be accounted for consistently.